Light Space

- New products

- Outdoor

- Controllers

▲Trophy for successfully passed the Lean Phase 1 audit awarded by Signify headquarters

At the beginning of 2019, Lei Fei’s management put forward the vision of “to be a world-class lighting factory” at the company’s first annual meeting after joining Signify and put forward the slogan of “Learning from Signify”. After 2 years of hard work, the company has reached the first milestone on the road to realize its vision.

Lei Fei Lighting officially launched the lean plan in July 2019. Although the project was suspended due to COVID-19, it still reached the Phase I goal in only 8 months. On June 18, both the Shenzhen and Foshan factories passed the strict acceptance audit conducted by Signify's Dutch headquarters and LEAN experts in Greater China and were awarded trophies and certificates.

The Shenzhen and Foshan factories passed the Lean Phase 1 acceptance audit quickly and with high quality, thanks to the efforts of Leifei's management team and the Lean team, which is composed of manufacturing, EHS, quality, supply chain. Experts from Chengdu factory, and Philos Fan, the Lean Leader of Signify Greater China, also provided valuable experience, technical support, and the patient guidance to Leifei. Their efforts have been recognized and appreciated by Signify's Lean experts.

▲Lean teams in Shenzhen and Foshan

Continuous improvement to resolve key gaps

Signify's lean implementation method is a phased and comprehensive operation model that solves key business activities, knowledge sharing and organizational agility in people and process systems by changing working methods and culture.

Lean deployment in manufacturing is divided into five stages: formation (select excellence), storm (excellent vision), specification (excellent foundation), transformation (excellent system), and execution (excellent practice). The goal of Lean Deployment Phase 1 is: Prepare for deployment, and key gaps are resolved.

In the past 8 months, following Signify's standards,the team used lean tools and principles and adopted a series of specific measures to greatly improve the Shenzhen and Foshan factories.

Specifically including:

1)Safety First mindset, Machine Safety improvement program

▲Bulletin board of safety regulations in production workshop

2)6S: standards, audits

▲Tidy workshop and well-arranged tools

3)Kaizen: lot of continuous improvement projects implemented, resulted in improved quality and productivity

▲One of the Kaizen continuous improvement team: Shenzhen "Pioneer" team

▲One of the Kaizen continuous improvement team: Foshan "No Welding defects" team

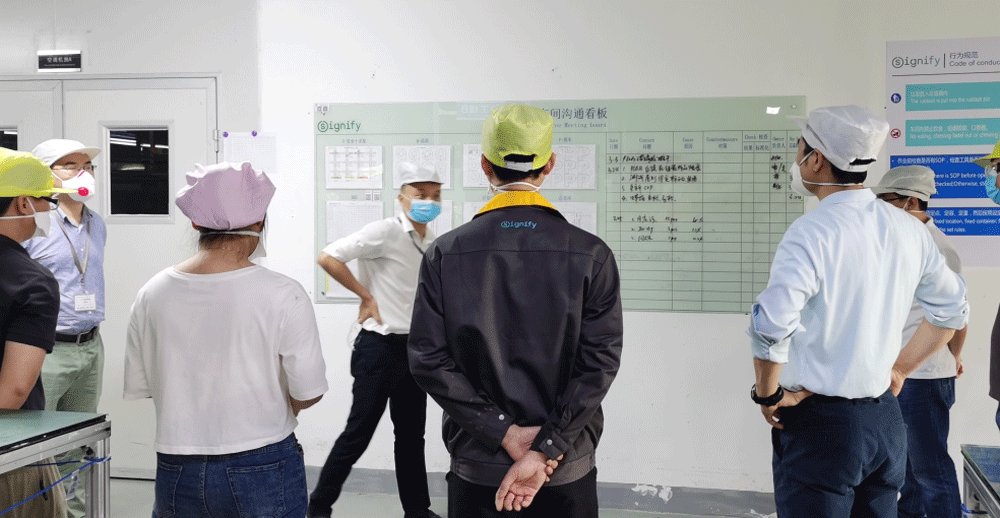

4)Daily Management Boards, loop meetings, 4C problem solving

▲Site communication team

5)Leader Standard Work implemented

▲Lean leadership training(Foshan)

6)VSM: current state mapped for model lines and kaizens identified

▲Value flow chart during the discussion

"Compared to the previous site (lean transformation), there is an excessively big improvement. Through rectification and hard work, the team uses the same theory to achieve efficient communication and uses lean tools to solve problems. The true north can be found correctly at each level of work. "——comments on on-site before and after transformation from a member of the lean team.

"The concept of management and grassroots employees has undergone a great change. After the lean transformation, on-site waste has been greatly reduced, and employees’ awareness of self-improvement has also increased a lot, and they will also take the initiative to put forward some improvement suggestions. The changes have made our production efficiency greatly improved.It has also made it easier for us to implement the follow-up lean implementation."-A member of the lean team evaluates the personnel before and after the lean implementation. ——comments from a member of the lean team.

“Leifei has a dedicated steerco team in place with strong leadership support to drive Lean as part of their Hoshin. ------comments from an experienced team, open for continuous improvement.

LiteMagic 微信号

关注公众号了解更多资讯